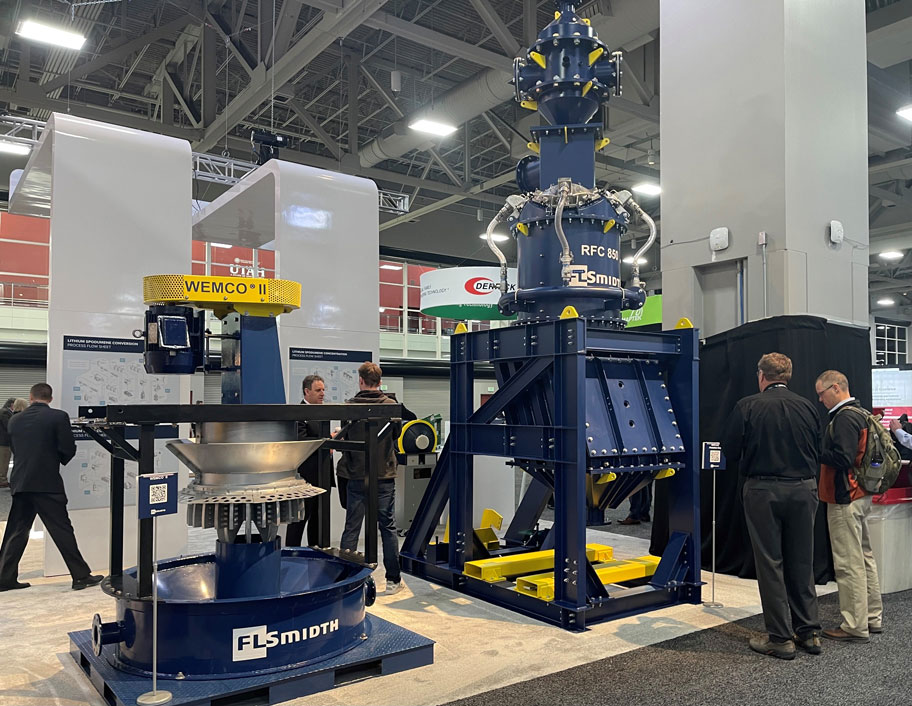

FLSmidth used SME 2022 in its U.S. hometown of Salt Lake City, Utah, to introduce two new products in flotation optimization, the WEMCO II and REFLUX Cell (RFC).

The WEMCO II flotation cell, the successor to the original WEMCO, features rotor and stator/hood optimizations for boosted power consumption, air flow and pumping.

The new release’s design features full air control without blower and froth maintenance, offering greater kinetic performance and lower operational costs for better hydrodynamics and circulation, improved kinetics and performance and optimized energy efficiency with the capability to control air without an external supply.

“For decades, WEMCO flotation cells have consistently delivered at the highest level when it comes to recovery,” FLSmidth said, confirming there are 40,000 machines globally.

“Now, WEMCO II’s combination of efficient aeration and optimum solids suspension increases recovery and concentrate grade performance, as well as reducing reagent consumption.”

Also taking its spot as a new product at SME 2022 was the REFLUX flotation cell, the smallest industrial scale version of the RFC with the ability to reduce a plant footprint as well as water, air and energy requirements.

The RFC, according to FLSmidth, reduces CAPEX by 35% with no direct power input; this results in 60% less energy use in a flotation circuit.

“Results from pilot-scale studies indicate that RFC technology can help mines use up to 60% less energy in their flotation circuits. Improved kinetic efficiency also reduces the amount of water used in the recovery process,” the company said.

The high-efficiency RFC can be applied across all minerals as a rougher, scavenger and cleaner.

Source: FLSmidth